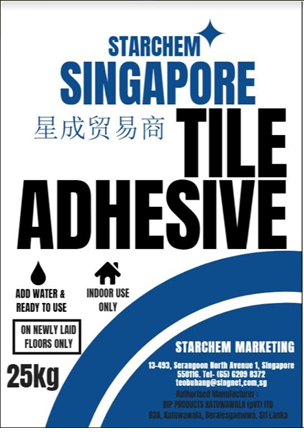

Cementitious, polymer modified general purpose tile adhesive

DESCRIPTION

Starchem Tile Adhesive is a grey cementitious powder containing performance enhancing polymers and other specialty additives. This versatile, easy-to handle, cement-based adhesive is perfect for fixing ceramic tiles, quarry tiles and similar materials. It provides strong adhesion to cement/sand screeds, to in-situ/pre-cast and aerated concrete, and brickwork.

RECCOMMENDED USES

- New tiling in internal areas & floors in external.

- Ceramics and decorative cladding.

- Showers & wet processing areas.

- Laboratories, hospitals, canteens, etc

- Tiling corridors, pavements and roofs

FEATURES AND BENEFITS

Water resistant – suitable for wet areas

High adhesive bond strength – suitable for larger tiles

Easy to use – just add water on site

APPLICATION

Surface preparation All surfaces must be clean, dimensionally stable, sound and free from all traces of oil, grease, mold release agent and curing compound. It should be ensured that tiles are dry, and free of contaminants that could impair adhesion.

Concrete, screeds, renders, and blockwork should be cured sufficiently that all shrinkage movement has occurred.

MIXING INSTRUCTIONS

Add 25 Kg of Starchem Singapore Tile Adhesive on to 6-7 Liters of water and mix well until it makes smooth paste. Keep the mixture for three minutes and sue within two hours.

PROPERTIES

Aspect – Free flowing grey powder

Fresh wet density – 1.75 kg/litre

Water/powder ratio, by weight – 0.18 – 0.210

Immersion foot traffic/ Groutable – 24 Hours at 25oC

Chlorine content – < 0.2%

APPLICATION INSTRUCTIONS

Apply Starchem Tile Adhesive to a uniform thickness of 3 to 6mm or sufficient to cover the studs or keys on the tile back; on a working area of not more than 1 m². Solid bed fixing is recommended for all horizontal applications and for ceramic tiles. If preferred, Starchem Tile Adhesive can additionally be buttered on the backs of the tiles to ensure full adhesive contact. For all other vertical applications the adhesive bed should be combed horizontally with a notched trowel to remove excess. Tiles should be dry and fixed by pressing into place with slight twisting motion, ensuring the tile back achieves full contact with the adhesive. Note: Do not apply over an area greater than that which can be covered within the open time of the product.

Ceramic tiles should never be butt jointed. Leave a minimum of 2mm around tiles. Adjustments to tiles should only be made during the adhesives open time. Remove excess adhesive from the face of the tile with a damp sponge or cloth before it sets.

Similarly, joints must be raked out in readiness for grouting. Leave for a minimum of 24 hours before grouting.

SAFETY PRECAUSIONS

As with all chemical products, care should be taken during use and storage to avoid contact with eyes, mouth, skin and foodstuffs. Treat splashes to eyes and skin immediately. If accidentally ingested, seek immediate medical attention.

STORAGE

Store out of direct sunlight, clear of the ground on pallets protected from rainfall. Avoid excessive compaction. Failure to comply with the recommended storage conditions may result in premature deterioration of the product or packaging.

Shelf Life – 6 months from date of manufacturing

Authorised Manufacturer and Distributor of

Starchem Tile Adhesive, Starchem Marketing Singapore:

DIP PRODUCTS KATUWAWALA (PVT) lTD

93A, Katuwawala, Boralesgamuwa. Sri Lanka.

Hotline: 0773083217

Visit: www.dipproductskatuwawala.com